When an application requires a rope that is built for abrasion resistance and longevity in tough conditions, look to Ultrex E. Advanced fiber technologies, engineering, and strategic fiber selection provides Ultrex Endurance with dependable strength and next level abrasion resistance, out performing other ropes especially in high abrasion environments. This rope is manufactured in the United States using premium imported HMPE fiber, providing improved sheave-cycling performance compared to other high-tech fibers.

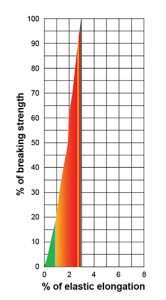

The 12-strand single braid construction of Ultrex Endurance, combined with optimized braid angles, and high denier yarns, are designed to provide Ultrex E with reliable and consistent break strength while keeping elongation low and durability high. To further enhance the abrasion durability of Ultrex E, fiber and strand-level coatings are applied during the fabrication process, greatly improving abrasion resistance and overall handling.

HMPE 12-strand single braid construction

Manufactured in the USA using premium imported high denier HMPE fiber

Fiber & Strand-level coated for improved abrasion resistance

High strength-to-weight ratio

Low elongation

Low water absorption

Lightweight and easy to handle

Easily spliced

Approved Splice Technique: #10015112, #10018009.

| Diameter (Inches) | Weight (Lbs/100f) | Spliced Minimum Breaking Strength (Lbs) | Unspliced Minimum Breaking Strength (Lbs) |

| 1/16 | 0.1 | 720 | 792 |

| 1/8 | 0.3 | 1,800 | 1,980 |

| 5/32 | 0.5 | 2,500 | 2,750 |

| 3/16 | 1.0 | 5,100 | 5,610 |

| 1/4 | 1.7 | 7,900 | 8,690 |

| 5/16 | 2.4 | 12,500 | 13,750 |

| 3/8 | 3.6 | 17,000 | 18,700 |

| 7/16 | 4.6 | 22,500 | 24,750 |

| 1/2 | 6.4 | 32,000 | 35,200 |

| 9/16 | 8.0 | 38,000 | 41,800 |

| 5/8 | 9.5 | 45,000 | 49,500 |

| 3/4 | 14.0 | 64,000 | 70,400 |

| 7/8 | 17.9 | 86,000 | 94,600 |

| 1 | 24.2 | 100,000 | 110,000 |

| 1-1/8 | 28.8 | 125,000 | 137,500 |

| 1-1/4 | 33.9 | 150,000 | 165,000 |

| 1-5/16 | 41.8 | 160,000 | 176,000 |

| 1-1/2 | 55.4 | 210,000 | 231,000 |

| Diameter (mm) | Weight (Kg/100m) | Spliced Minimum Breaking Strength *(kg) | Unspliced Minimum Breaking Strength (kg) |

| 2 | 0.1 | 325 | 358 |

| 3 | 0.4 | 810 | 891 |

| 4 | 0.7 | 1,100 | 1,210 |

| 5 | 1.5 | 2,300 | 2,530 |

| 6 | 2.5 | 3,500 | 3,850 |

| 8 | 3.6 | 5,600 | 6,160 |

| 10 | 5.4 | 7,700 | 8,470 |

| 11 | 6.9 | 10,000 | 11,000 |

| 13 | 9.5 | 14,500 | 15,950 |

| 14 | 11.9 | 17,000 | 18,700 |

| 16 | 14.2 | 20,000 | 22,000 |

| 19 | 20.9 | 29,000 | 31,900 |

| 22 | 26.7 | 39,000 | 42,900 |

| 25 | 36.1 | 45,000 | 49,500 |

| 29 | 42.9 | 56,000 | 61,600 |

| 32 | 50.5 | 68,000 | 74,800 |

| 33 | 62.3 | 72,000 | 79,200 |

| 38 | 82.5 | 95,000 | 104,500 |

* Knots and abrupt bends significantly reduce the strength of all ropes and lower the maximum working load.

Specific Gravity: 0.97

Dielectric Strength: The maximum allowable leakage for clean, dry Ultrex is 75 micro-amperes when tested at 100kV per Yale Method 712-1701 Rev 1 “Routine Production Test.” Absorbed and entrained moisture or impurities will increase the rope’s conductivity dramatically.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |