Full Rope Inspection Guide

This page covers construction and inspection information for single braid, balanced double braid, high modulus double braid, parallel core and 8-strand plaited ropes.

Download the full Rope Selection and Inspection Guide (10.3 MB)

Single Braid

Yale’s single braids expose their strength to abrasive attack from the day they are put into service. For that reason, regardless of fiber, they need to be inspected regularly, then downgraded, repaired or replaced to maintain their design factor.

Single braid products: Aracom 100, Lugger Line , Maxibraid, PE-12, PolyPlus Braid, Shark Byte, Ultrex, Vectrus, and Yalex

Download the Single Braid Inspection Guide (3 MB)

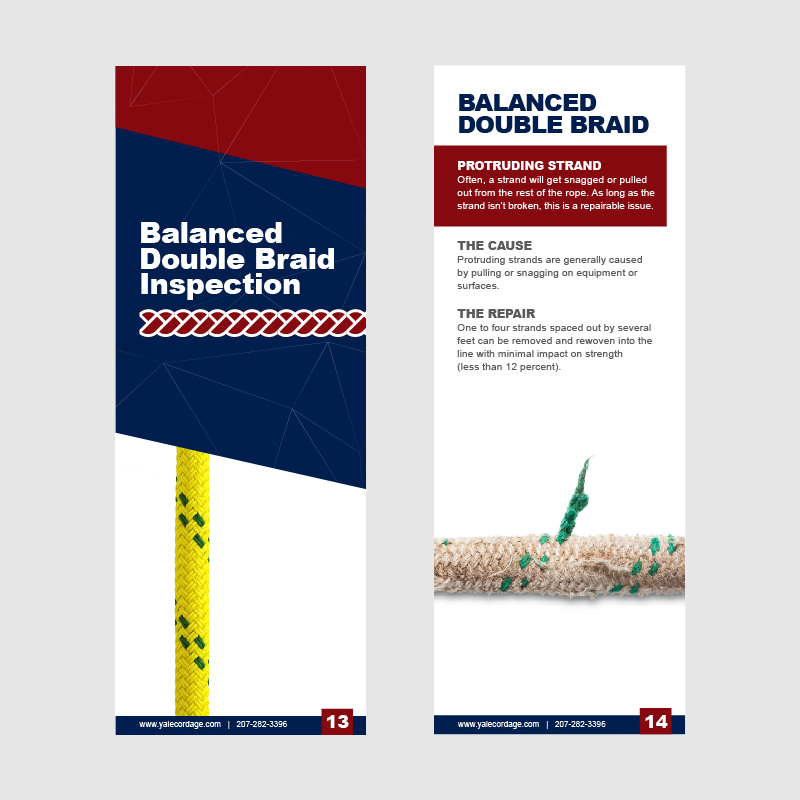

Balanced Double Braid

Yale’s balanced double braids depend equally on the integrity of the rope’s core and sleeve elements. If either is compromised, the design factor is negated and the remaining overworked fibers will degrade more rapidly.

Balanced double braid products: Double Esterlon, Kernmaster, Polydyne, Portland Braid, Tech-Kern, and Yalon

Download the Balanced Double Braid Inspection Guide (2.2 MB)

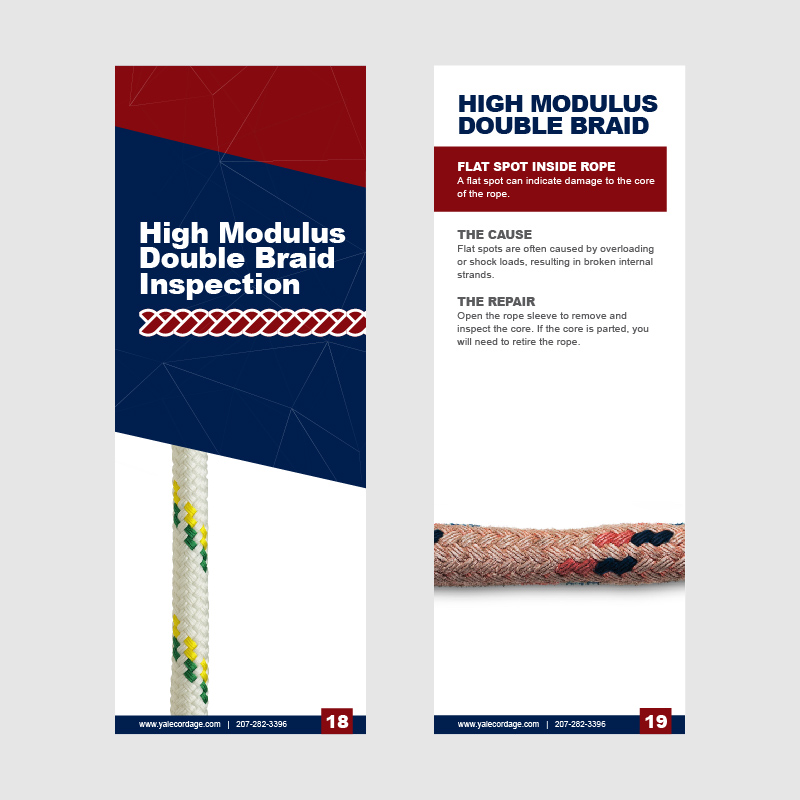

High Modulus Double Braid

Yale’s high modulus double braids depend solely on the rope’s core elements for their strength. The covers supply abrasion protection for the high-tech core fibers. Therefore, proper inspection must consider the condition inside the rope.

High modulus double braid products: Aracom Miniline, Aracom T, Crystalyne, Maxibraid Plus, and Ultrex Plus

Download the High Modulus Double Braid Inspection Guide (2.1 MB)

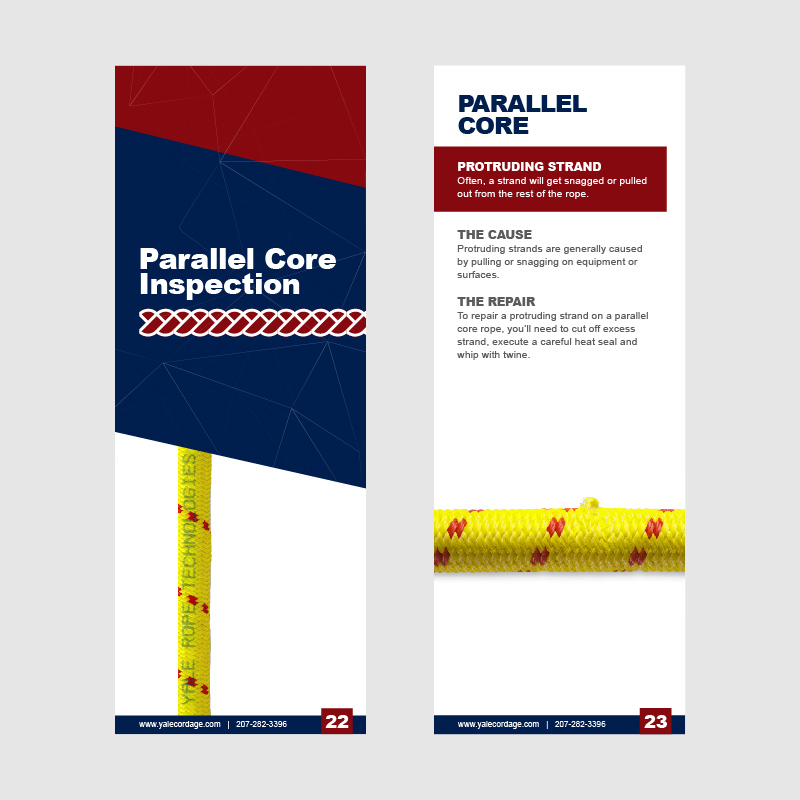

Parallel Core

Yale’s parallel core ropes depend on their core’s integrity to maintain breaking strengths. Most damage to the outside of the line is not serious but should still be addressed to prevent further damage.

Parallel core products: Uniline and Unitrex XS

Download the Parallel Core Inspection Guide (2 MB)

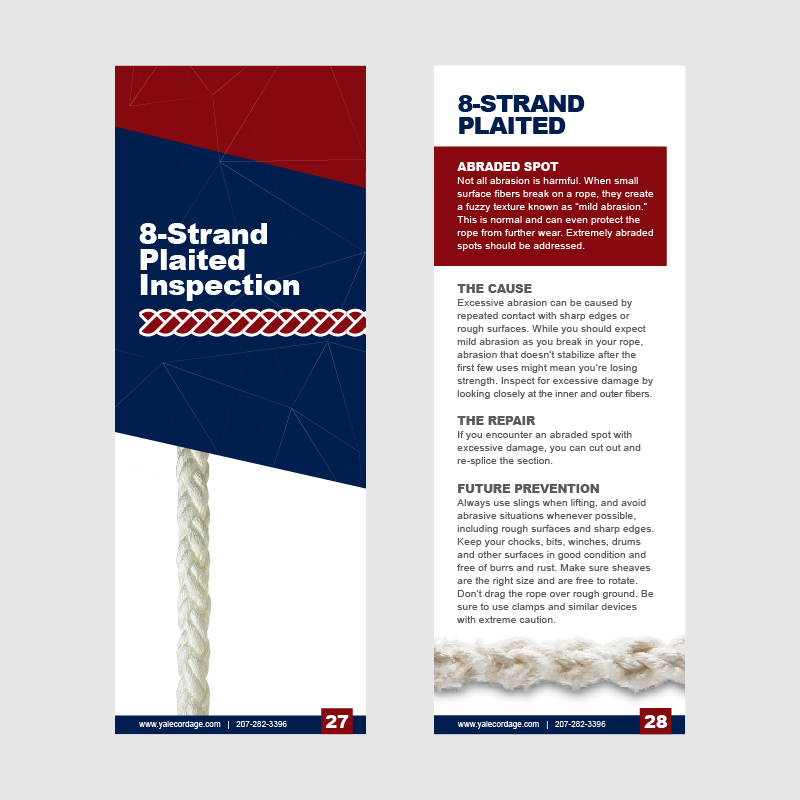

8-Strand Plaited

Yale’s 8-strand ropes are similar to single braids, as all of their fibers are periodically exposed on the surface of the rope. As surface fibers are abraded, the rope loses weight and becomes weaker.

8-strand plaited products: Nylon Brait, Oceanographer’s Brait, and Unitrex XS-8

Download the 8-Strand Plaited Inspection Guide (1 MB)